Polypeptide Manufacturing with SUMO

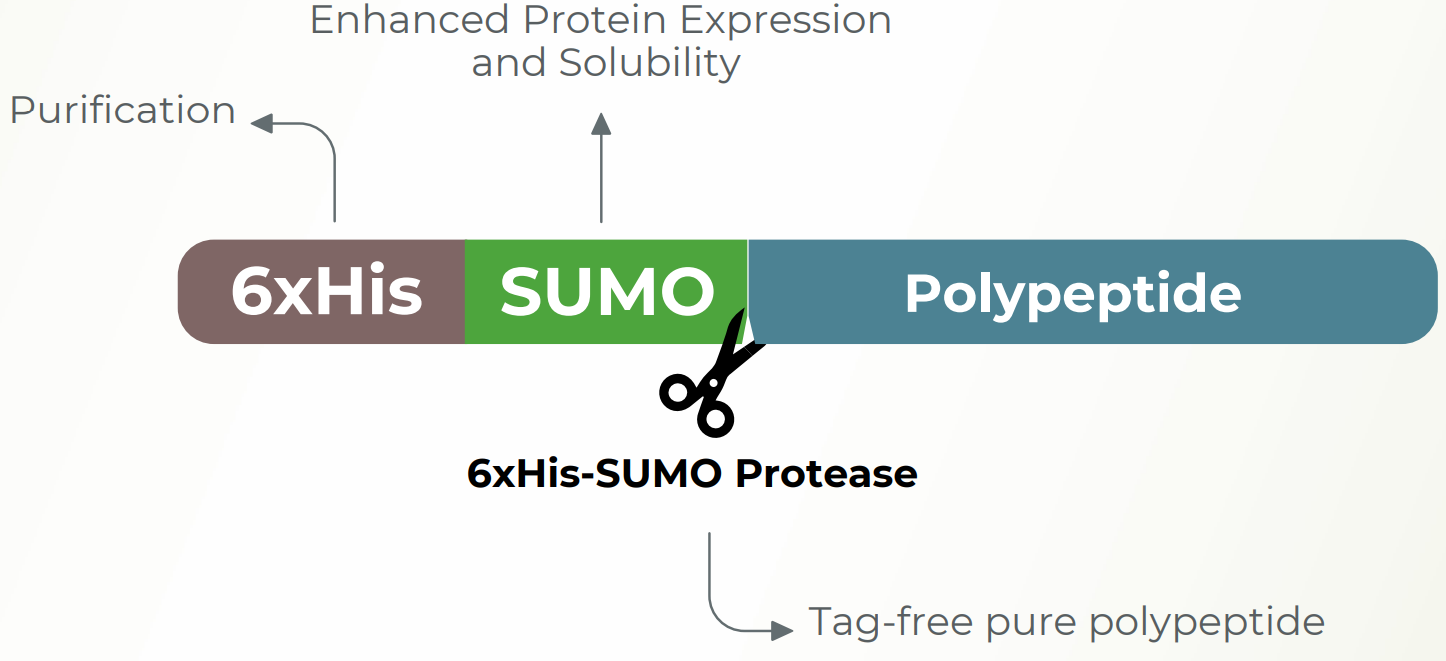

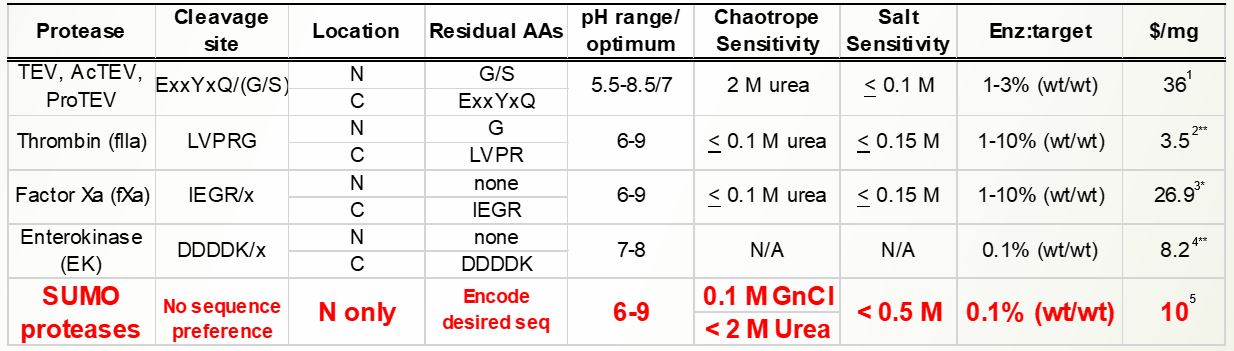

Polypeptides are commonly synthesized by traditional chemistry. There are a few disadvantages of chemical synthesis of polypeptides: 1) errors occur in sequence with certain amino acids during chemical synthesis, 2) not all chemically synthesized peptides fold correctly, and 3) yield of polypeptides decreases along with the length of the polypeptide. SUMO system has been proven as the best method for recombinant production of polypeptides, especially longer peptides.

Click to Read More: Benefits of SUMO

1) Stabilize polypeptide to increase the yield

2) Encode desired N-terminal sequence

3) Ensure a correctly folded polypeptide due to SUMO chaperoning properties.

SUMO system is the most cost-effective way to manufacture growth hormones, glucagon-like polypeptides, and anti-microbial and industrial polypeptides. Contact LifeSensors to decrease the cost of goods for your polypeptide production. We will guide you about the best way to manufacture your polypeptide and transfer the manufacturing process to GMP sites.